Sustainable Packaging

|

Work towards 100% reusable, recyclable or compostable packaging by the end of 2030

The way our foods are packaged ensures their safety, freshness and great taste. We are passionate about managing our packaging footprint towards greater circularity, helping to minimize waste and ensuring as much packaging as possible is reused, reduced or recycled.

Our Commitment

As part of our Kellanova Better Days™ Promise goal to create better days for 4 billion people by the end of 2030, we will work towards 100% reusable, recyclable or compostable packaging (by volume) by the end of 2030.

Kellogg Company introduced recycled cereal boxes in 1906. Over 117 years later, Kellanova remains committed to working to reduce our packaging impact to nurture our planet.

Our Approach

Kellanova has one of the smallest plastic packaging footprints among peer food companies and is a signatory to the Ellen MacArthur New Plastics Economy Global Pledge.

In addition to designing our packaging to be sustainable, we know that we need to help develop recycling infrastructure and help improve consumer recycling behavior. We take seriously our responsibility to champion education and build partnerships in this space.

Our framework involves four approaches:

- Reduce packaging usage across our portfolio by decreasing total packaging weight wherever possible.

- Remove certain plastic items and packaging materials. This includes all single-use foam and plastic service ware, straws, and bottles at our global facilities; single-use plastic cutlery from food packaging; and exclusion of single-use plastic straws, stirrers, polystyrene and oxo-degradable plastics from food packaging.

- Redesign packaging to be recyclable or compostable.

- Increase Recycling: The percentage of plastic packaging that is designed to be recycled has increased year-over-year, but there is additional work to be done. Recycling rates for plastics are low across the board, particularly for materials that could be recycled if the infrastructure existed (recycle-ready1).

We are working to help fix the low recycling rates of plastics and lack of infrastructure in several ways:

- We leverage our global scale and voice to engage our suppliers, original equipment manufacturers and technology companies on delivering sustainable packaging solutions that maintain our food safety and shelf-life requirements.

- Educating consumers about what they can recycle and how.

- Finding and developing new packaging technologies that are reusable or work within the existing recycling infrastructure.

- Securing supply of recycled plastic and evaluating fit within our portfolio.

- Engaging and collaborating with peer companies, recycling industry partners and packaging suppliers to increase access and support for infrastructure and innovation.

- Global

- Ellen MacArthur Foundation New Plastics Economy Signatories

- Regional engagement and infrastructure support

- Australian Packaging Covenant (APCO) APCO Members

- CEFLEX CEFLEX Stakeholders

- Holy Grail 2.0 (Holy Grail Full Members)

- Sustainable Packaging Coalition SPC Members List

- Association of Plastics Recyclers APR Members

- Michigan Recycling Coalition MRC

- Polycoated Paper Alliance

Our Challenges

While Kellanova has significant efforts underway to address waste and plastics across our value chain, we cannot accomplish our ambitious goals alone. We collaborate with new and existing partners, customers and other innovators to identify packaging solutions that protect and enhance our foods while delivering on the quality and great taste that people expect from Kellanova.

Unlike many other food manufacturing companies, Kellanova’s plastic footprint by weight accounts for only 11% of our total packaging usage. Some of our plastic is designed to be recycled, in line with Ellen MacArthur definitions. However, the majority is flexible plastic, which is “recycle ready”1 and could be recycled if adequate infrastructure existed. We aim to change this in two ways: redesigning our plastic packaging to suit the current capabilities of the recycling infrastructure and advocating for an improved recycling infrastructure for flexible packaging.

Part of our approach is to increase our use of recycled plastic packaging, yet today we only use a small percentage. There are two main challenges in this space. First, because our use of plastic is small to begin with, sourcing the small available quantities of recycled plastic is difficult. Second, given we are packaging food, and not household items, we must ensure that we are safely using recycled content in line with varying food safety regulations across the globe. We are working with key partners to identify sources of recycled content for use in our packaging to enable us to grow our use of recycled plastic.

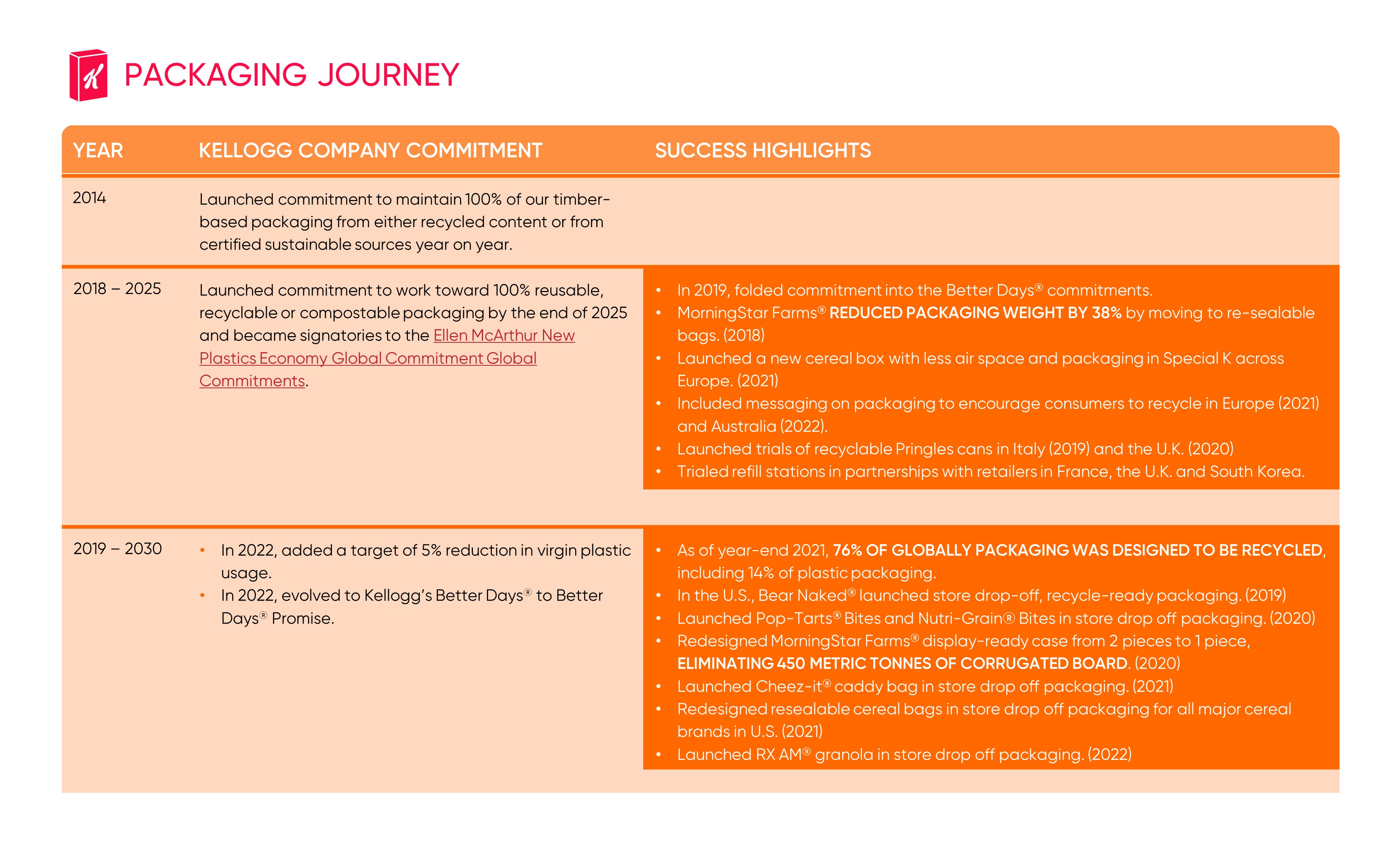

Our Journey

Kellanova is a new company with a foundation that’s more than a century long. We are committed to carrying forth the legacy of Kellogg Company, who led with purpose to create a positive impact for people and planet. Like our name signals, we’re building on that legacy of doing good, built over the previous 117 years, while looking ambitiously toward the future.

Progress reported below is for Kellogg Company through the end of 2022. Kellanova will report on progress toward our commitments in our initial Social and Environmental Report that we will issue in 2025.

1 Recycle-ready is defined as packaging designed to be compatible with the infrastructure in a specific country or region, but the infrastructure is not yet widely available (does not meet the minimum 30% recycled rate)